We are an internationally renowned manufacturer of hot forged industrial fasteners. Our patented bolting products are trusted for their quality, performance and reliability. At Valley Forge, we have developed patented technologies that will completely change your way of thinking about a bolted joint. Our manufacturing technologies give you the ability to monitor direct load in the fastener while it is in service. This capability will completely revolutionize your application. The money you will save in knowing exactly what your bolts are doing under load, gives you joint integrity, less down time, and safe performance of your equipment. We are a quality based, US manufacturer that focuses on solving problems and doing it in a first class manner.

Knowing exactly what your bolts are doing under load, gives you joint integrity, less down time, and safe performance of your equipment.

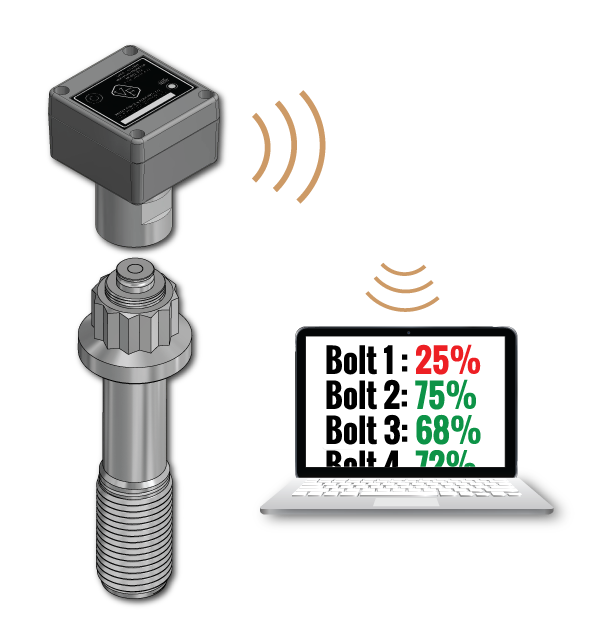

SEE THE REVOLUTIONOur manufacturing technologies give you the ability to monitor direct load in the fastener while it is in service, no matter the application with the SPC4®.

CONTROL THE REVOLUTION

The wireless SPC4® assembly has the ability to monitor load from a great distance. Whether its from across the job site or to your corporate office, the entire assembly is designed for your specific application and tailored to your needs.

MONITOR WIRELESSLY

Designing patented industry solutions for over 30 years is hard work. With over 16 awarded patents, we can change your way of thinking about bolting. Ask us today about how we can find a solution for your application.

LET US FIND YOUR SOLUTION

- Valley Forge & Bolt Launches Android Application Accessory for SPC4® Load Verifying System

- Developments for Milling Bolting Applications | minEXPO 2021

- UNDERSTANDING THE STANDARD: ACCURACY TO THE LETTER

- Valley Forge & Bolt Introduces SPC4™ 406A Handheld Meter

- Valley Forge & Bolt Introduces High Temp Maxbolt®