The Latest At Valley Forge

After a simple set up and calibration, users can configure the app with their specific equipment and site details to monitor target clamp load during both fastener installations and routine inspection. This improved load monitoring method allows end users to pinpoint problems, optimize installation time, reduce downtime, and share data with key stakeholders at any time.

After a simple set up and calibration, users can configure the app with their specific equipment and site details to monitor target clamp load during both fastener installations and routine inspection. This improved load monitoring method allows end users to pinpoint problems, optimize installation time, reduce downtime, and share data with key stakeholders at any time.

Explore a scaled, 3D animated ball mill rendering of our latest developments in milling bolting applications

With over 45 years of bolting experience in mining milling applications, the fastener experts at Valley Forge & Bolt Mfg. Co. have got you covered. A wide array of bolting solutions is making costly and time-consuming downtime in grinding mills a thing of the past. From liner bolt sealing solutions to flange hardware, we continue to lead the industry with a constant feed of new innovations.

As IOT and remote condition monitoring become more mainstream, Valley Forge & Bolt Mfg. Co are bringing wireless bolt monitoring solutions, which include the tension over torque advantage, to the mining industry.

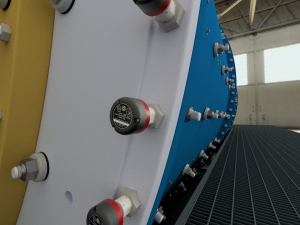

Ball Mill rendering featuring Valley Forge Wireless Meters and SPC4 load indicating on flange

Visit booth 1122 at minEXPO and explore a scaled, 3D animated ball mill rendering of our latest developments in milling bolting applications, including the introduction of the Flange Manager Pat. Pend.. We are also showcasing our patented SPC4® load indicating fasteners with the latest addition to the company’s RTM™ (Remote Tension Monitoring) series of meters—the UHF Band 720R™ RTM Meter, a wireless bolt monitoring system which operates in 433/868/915 MHz frequencies and is fully remotely configurable.

Why ASTM-Complying Fasteners Are Important For Critical Joints

Industry is ruled by standards, overseen by a number of national and international standardizing bodies. Whether it’s ISO (the International Organization for Standardization), DIN (Deutsches Institut für Normung), ASME (American Society of Mechanical Engineers), ANSI (American National Standards Institute), or ASTM (American Society for Testing Materials), each serves a specific purpose.

Here, we’ll be taking closer look at ASTM, specifically the ASTM F2482 Standard. ASTM’s abstract describes this specification as covering “externally threaded … fasteners, capable of indicating clamping forces up to yield strength during the tightening process or post installation residual tension, or both.” In other words, fasteners that indicate tension.

ASTM is the largest organization in the world for developing and publishing voluntary, full-consensus

standards. It has been around for more than a century and is well known and highly respected in many industries. Its process for creating new standards requires collaboration among industry participants to develop and finalize language and standards, then a wider vote to accept it. In 2002, Valley Forge & Bolt, maker of patented bolting products, recognized the importance of having a consensus standard detailing the requirements for load indicating fasteners and approached a subcommittee of the F16 Committee on Fasteners. After two years, peer collaboration, and several ballots, the standard was accepted.

Currently, 17 years after the acceptance of the ASTM F2482 Standard, Valley Forge products are still the only ones that comply with the specification that fasteners accurately measure tension as a percentage of load to within +/-5%. Those products are Maxbolt® and SPC4®.

Valley Forge director of engineering James Brooks says meeting the ASTM F2482 Standard has benefits for both the manufacturer and the customer. “These are critical measures of accuracy and precision,” said Brooks. “We believe there are distinct advantages to being compliant. In addition, the standard provides control of other essential areas such as material, manufacturing process, testing and calibration, inspection and certification.”

“If the customer is serious about controlled bolting for their critical joints, it will be important to them that the fasteners they use achieve the +/-5% accuracy standard,” said Brooks. “It is for applications where reliability, safety, and certifiable product performance are critically important.”

The ASTM F2482 standard promotes safety by its sheer accuracy at measuring tension from within the critical joint. Because Maxbolt® and SPC4® can literally tell maintenance personnel, by percentage of load, how close they are to appropriate tension, those maintenance workers can make timely, better-informed decisions about when to re-torque, replace, or leave bolts alone. This extends fastener life and helps to prevent machinery and equipment from operating with bolts that are out of tension—the leading cause of bolt failure.

Brooks says the Valley Forge Maxbolt® and SPC4® occupy a unique space in the current ASTM F2482 standard among mechanical and electronic type fasteners, as competitors generally can only deliver +/-25% accuracy. “At that point, you’re getting roughly the same tension accuracy achieved by using only a torque-based solution, so it makes little sense to invest in tension-measuring fasteners,” said Brooks. “Whereas Maxbolt® and SPC4® deliver much greater precision, at +/-5%, enabling the user to realize the benefit of the tension versus torque advantage.”

Thanks to ASTM F2482, customers with critical joints are assured of precision fastener solutions that can achieve and display clamp load to within +/-5% accuracy, and that are designed and manufactured to do so in a host of applications.

Valley Forge & Bolt Mfg. Co. manufactures patented bolting products for critical applications. Products are widely trusted for their unrivaled quality, extraordinary performance, and enduring reliability. Call: 1 (602) 269-5748. On the web: https://www.vfbolts.com/.