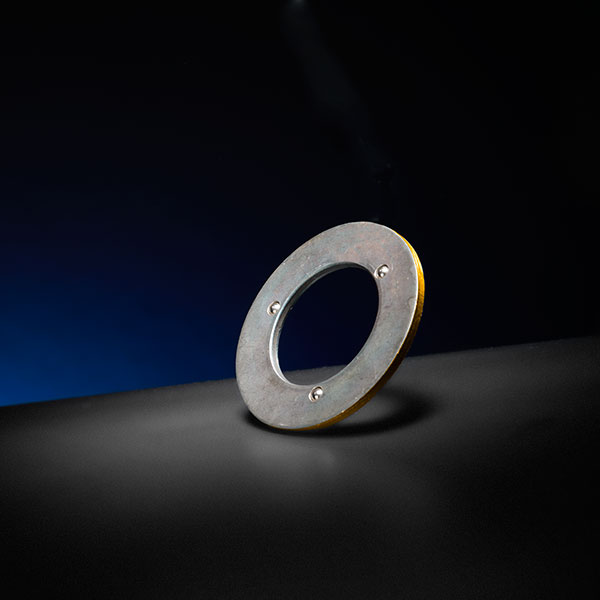

The Ball Lock Washer is a hardened washer, which employs the use of hardened steel ball bearings that embed and grip into the flange face and nut bearing surfaces. This mechanical lock begins to occur during the hand tightening stage and is maintained throughout the tightening process. The length of time it takes to assemble a joint is greatly reduced since the operator can quickly maneuver a single tool around the flange. This unique system works both when tightening and loosening. It can be used under the nut, when tightening the head, or used under the head, when tightening the nut. The result is a technology that eliminates the need for a back-up wrench and the need for an operator to place his hands and fingers at risk in a pinch point zone.

The Ball Lock Washer is a hardened washer, which employs the use of hardened steel ball bearings that embed and grip into the flange face and nut bearing surfaces. This mechanical lock begins to occur during the hand tightening stage and is maintained throughout the tightening process. The length of time it takes to assemble a joint is greatly reduced since the operator can quickly maneuver a single tool around the flange. This unique system works both when tightening and loosening. It can be used under the nut, when tightening the head, or used under the head, when tightening the nut. The result is a technology that eliminates the need for a back-up wrench and the need for an operator to place his hands and fingers at risk in a pinch point zone.

The use of back up wrenches accounts for a significant amount of lost time accidents in any industrial bolted joint setting. Pinched and severed fingers are commonly associated with tightening or loosening of a bolted joint. When the hydraulic or pneumatic turning method overcomes the strength or balance of the operator who holds the back-up wrench, the operators’ safety can be compromised. From a reliability standpoint, it is often the case that there is not ample clearance on the backside of the flange to install a back-up wrench. In these cases, the operator typically turns the front nut until enough friction is naturally generated to hold the nut and tighten the fastener. This scenario does not give a high level of assurance that the fastener stress has been created in the joint and can often lead to joint failure and leakage. If a situation exists where the operator cannot access the backside of a flange because of clearance issues, the technology allows the operator to safely and efficiently generate the fastener stress by locking the back nut.

“A Craftsman’s friend, an Engineer’s partner and a Safety Manager’s dream.”

– Lamons