When Grinding Mills age, the location in the shell for liner bolt nuts can become worn. This can cause slurry leakage. Slurry leakage is a real problem. It cuts through the shell and makes the leak grow and grow: a viscous cycle. By using our Pitbull™, this can mitigate any more damage from happening until there can be a complete repair of the hole created from a bolt boring around.

When Grinding Mills age, the location in the shell for liner bolt nuts can become worn. This can cause slurry leakage. Slurry leakage is a real problem. It cuts through the shell and makes the leak grow and grow: a viscous cycle. By using our Pitbull™, this can mitigate any more damage from happening until there can be a complete repair of the hole created from a bolt boring around.

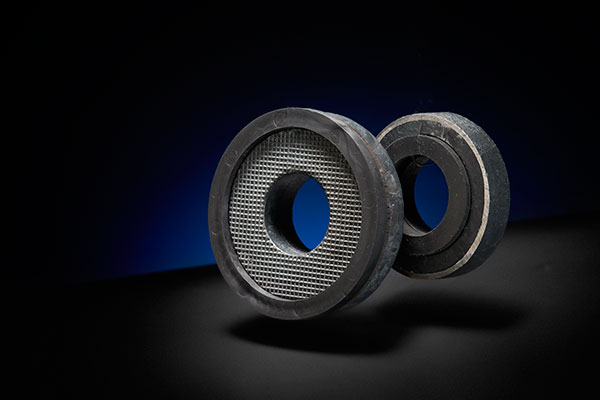

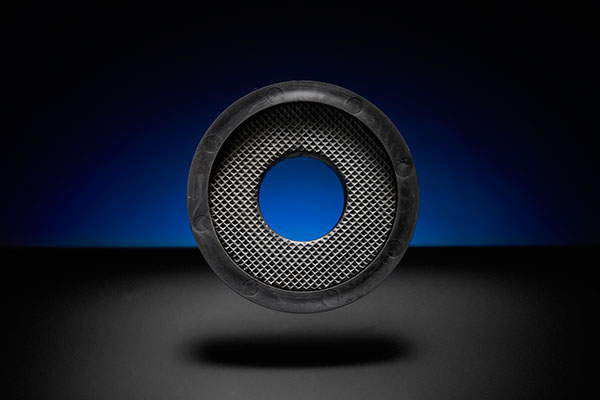

Our Pitbull™ Liner Washer grips and holds like no other washer can. The Pitbull™ Liner Washer is one of our most popular washers because they hold like a “pitbull’s bite”, and provides that stable platform needed in worn areas. In addition, for bolt diameters of: 1 ¼”, 1 ½”, 2″ (M48 and M52), we even have an Oversized Pitbull™ made to cover a badly worn bolt hole area, on the shell.

Our newest creation, in this respect, is a Double Sided Pitbull™ Liner Washer. This washer was developed because, often times, a liner bolt is not initially manufactured long enough to allow for both the Pitbull™ Liner Washer and the Two Piece Sealing System to fit. Then, when an enlarged shell hole occurs as the mill ages, and needs a Pitbull™, the liner bolt must be replaced with a new, longer bolt to accommodate both systems. Now there is another option. The Double Sided Pitbull™ is the solution to accommodate both systems without requiring an entirely new, longer bolt.