The Latest At Valley Forge

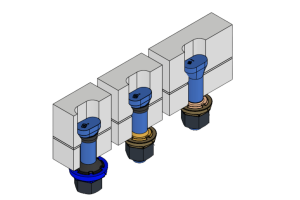

The Modular Sealing Washer System is an adaptive mill sealing system for liner bolt holes, available in two standard sizes and one oversize option. This range in sizing options provides the versatility necessary to allow mill mechanics to select the appropriate seal based on the condition of their mills.

Over time, liner mounting holes become elongated and enlarged, which creates opportunities for slurry leakage.

Why Do Mill Liner Bolt Holes Leak Over Time?

Even with proper installation, several mechanisms are working against a perfect seal:

- Cyclic loading & vibration – Mills experience constant impact and shell flexing, which can relax bolt preload and break down sealing interfaces.

- Wear and erosion – Slurry is extremely abrasive, causing any exposed gaps around bolts, washers, or sleeves to slowly erode and increase leak paths.

- Bolt preload loss – Thermal cycling, liner wear, and settling all have an impact on clamp force. Once a preload drops below a critical level, slurry will infiltrate.

- Corrosion – Corrosion under washers or sleeves can create capillary paths, especially in acidic or chloride-rich slurries.

- Installation variability – Even the smallest of inconsistencies in torque, surface cleanliness, or alignment can shorten the seal life.

Despite these factors, good design and maintenance can prevent leakage and extend the seal life of each bolt hole. This is why modern mills are increasingly focused on bolt load verification, improved sealing assemblies, and predictive maintenance rather than reactive slurry cleanup.

How to Stop Slurry Leakage in Mill Liner Bolt Holes with a Modular Sealing Washer System

As mill diameters increase, a higher load is required to keep liners in place; some liner manufacturers require up to 200,000 pounds of bolt preload for larger SAG mills. These high load amounts can prematurely deform the steel retaining washer, which is why Valley Forge & Bolt engineered our new Modular Sealing Washer System to withstand more than 225,000 pounds of load without plastic deformation. Our washer is also strategically forged instead of cast, which is much better-suited to withstand higher loads. Lister washers and other cast washers found in the field have created many of the problems that our Modular Sealing Washer System now solves.

Relining your mill takes valuable time, and any inefficiencies in the process will cost you production time and, ultimately, revenue. Every process improvement in your mill environment equates to more operating hours each year. Our system is configurable to provide a solution for your sealing needs regardless of the condition of the liner mounting holes, and is designed to easily handle the highest load values specified by the OEM and liner manufacturers.

Let us help!

Are you experiencing issues with slurry leakage in your mill liner or a loss of load from washer deformation? Let us help! We’d like to offer you some modular sealing washer sets to test at your mill processing site. Simply fill out the form below and our team will respond with the next steps!

Here at Valley Forge & Bolt, we’ve been manufacturing the fasteners that supply the mining industry for the last 50 years, and our innovative technologies will completely change the way you think about a bolted joint. In the fast-paced world of mining, efficiency and safety are paramount. With the advancement of technology, continuous load monitoring of bolts is revolutionizing how we manage the integrity of critical components on mining sites.

Among its many benefits, our SPC4® Load Indicating System enables users to measure fastener tension locally or remotely using the Valley Forge & Bolt line of meters. Our full range of meters and sensors suits most budgets and applications, each capable of reading every SPC4® fastener. Most recently, we’ve taken our SPC4® Load Indicating Technology to new heights with the latest 720R Meter, a wireless bolt monitoring system that provides a cutting-edge solution for ball mills, crushers, flanges, and even haulage trucks operating on mining site environments where visibility to bolt health is more restricted. The 720R Meter includes a web-based user interface where engineers can monitor bolt load in real time. Parameters can be changed for each sensor remotely from a computer, tablet, or smartphone. Adjust the data sampling rate at any time with ease, and add new units as needed for complete scalability, even after the system is installed!

The Power of Real-Time Data

One of the standout features of the 720R Meter is its ability to provide real-time data reports that are accessible from anywhere in the world via a simple web browser. This means that mining site operators can monitor the health and performance of bolts from any computer, tablet, or phone in real time, without being on-site. The convenience of accessing live data remotely empowers teams to make informed decisions quickly, enhancing operational efficiency and safety.

Significant Cost and Time Savings

How much would you save by knowing a fastener is starting to lose tension? Traditionally, ensuring that bolts are properly tightened and maintained involved time-consuming manual testing for torque using instructions from a manufacturer, or an inaccurate ultrasonic measurement of fastener stretch. Technicians had to be physically present to conduct these assessments, leading to costly downtime and delayed operations. The 720R Meter eliminates this need. By continuously monitoring load and tension on bolts, our solution allows for proactive maintenance management on mining sites. This shift not only saves considerable time but also translates to significant cost savings, as resources can be allocated more efficiently.

Enhanced Safety and Reliability

In mining operations, the integrity of machinery is critical to ensuring safety and reliability. The 720R Meter plays a vital role in preventing equipment failure, which can result in costly repairs and potential safety hazards. By continuously monitoring the load on bolts, maintenance teams on mining sites are alerted to any anomalies that may indicate potential issues before they escalate, thereby enhancing the overall safety of the environment.

Conclusion

The 720R Meter is more than just a product; it’s a transformative solution for the mining industry. By harnessing the power of real-time monitoring and eliminating manual testing, the 720R Meter enhances operational efficiency, reduces costs, and ensures the safety of ball mills, crushers, flanges, and haulage trucks. As the mining sector continues to embrace automation and technology, the 720R Meter stands out as an essential tool for modern operations, paving the way for a safer and more efficient future.

In today’s competitive mining landscape, don’t get left behind—invest in the 720R Meter and unlock the full potential of your mining operation.