The Latest At Valley Forge

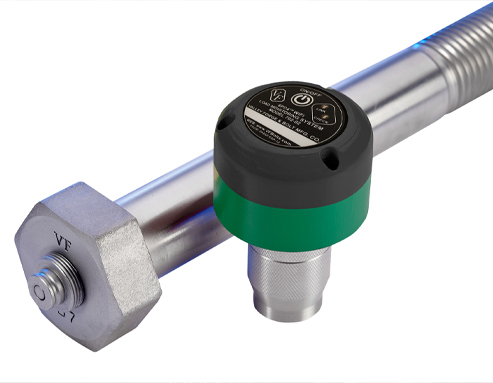

Phoenix, AZ—Valley Forge & Bolt, a domestic manufacturer of patented bolting products for critical applications, introduces the newest meter for its SPC4™ Load Verifying System. The SPC4™ 406A Electronic Meter (VF# SPC4-ASM-406A) is specially designed for accurate performance in heat, humidity, and other demanding environments.

The SPC4™ system encompasses fasteners equipped with Valley Forge load-indicating technology along with a wide variety of meters to fit a range of applications and environmental conditions. The meters, including analog, digital, or Wi-Fi versions, measure tension directly from within the fastener to +/- 5% accuracy. The 406A meter joins this complete offering.

In total, the SPC4™ system provides the most accurate information possible about the actual load within critical joints. In the field, this information is used to make both installation and maintenance faster and more accurate, create more effective maintenance schedules, and give crucial, early insight into fastener and equipment behavior that might lead to premature failure, allowing it to be corrected before problems arise. The net gain is increased productivity, performance, and safety combined with savings of time and money.

The 406A meter, which is already in use in mines in South America, boasts a rugged design with a shock-resistant casing that is IP54-rated for protection against dust and particles. Its internals are specifically engineered to deliver high performance in hot and humid conditions like those often found in mining and oil and gas applications. Bluetooth compatibility provides scalability for remote data monitoring and data logging capability.

“SPC4™ technology has been embraced by customers throughout the mining and oil and gas industries,” said James Brooks, Valley Forge & Bolt’s director of engineering and new business development. “With the 406A, our aim was to create a meter with the extra durability these environments need while still maintaining the high degree of accuracy people expect from Valley Forge.”

The ergonomic handheld design was built for ease of use in the field; its one-touch operation is easy to engage without removing PPE gloves, and a large digital display allows for easy reading.

Brooks says Valley Forge has accomplished its goal with the 406A, and he’s eager to see what other industries will embrace it. “This meter easily stands up to extreme environmental conditions. Its proving ground was in mining and oil and gas, and we expect it will perform impressively in other demanding environments,” said Brooks.

To learn more about the complete lineup of Valley Forge & Bolt Load Indicating Fasteners, visit https://www.vfbolts.com/.

Up to 650° F for extended run time and thermal cycling

Valley Forge & Bolt, America’s leading manufacturer of load indicating fasteners, is proud to announce the new High Temp Maxbolt®. The robust performer is able to operate in temperatures up to 650° F for near limitless applications and proven performance in extended high temperature run times and thermal cycling.

The new High Temp Maxbolt®, like the original Maxbolt®, helps to reduce downtime, premature wear, and catastrophic joint failures in critical industries—including processing, mining, and energy. Maxbolt® products feature a built-in analog gauge. At a glance, installation technicians know when proper load is achieved. During operation, technicians literally see if load ever falls out of spec on any bolt, addressing the need immediately instead of waiting for critical equipment failure.

With an accuracy of +/- 5%, compliant with ASTM F2482, the High Temp Maxbolt® provides real-time tension indication where process and environment may result in elevated temperatures. Employing all similar materials, a high-temperature lens, and easy-to-read gauge, High Temp Maxbolt® operates both in rapid thermal cycle applications and in prolonged high-temp situations.

“We know customers have been eager for a high-temperature version of Maxbolt® because they value the safety and time-savings it brings to their applications,” said James Brooks, Valley Forge & Bolt’s head of engineering and business development. “We’re pleased that we have combined the right blend of materials and precision worthy of the Maxbolt® name.”

High Temp Maxbolt® is available in all the standard diameters and grades as original Maxbolt®.

Prevent beachmarks and bolt failure with load indicating fasteners

Prevent beachmarks and bolt failure with load indicating fasteners

Working at a gold mine isn’t always a day at the beach. In fact, so-called beachmarks are a sign that things are going terribly wrong. Beachmarks are the stress marks visible on grinding mill liner bolts when they fall out of appropriate tension, caused by the constant flexing back and forth in the hole. The appearance of beachmarks is a sign that the bolt is about to fail. Unfortunately, most of the time they aren’t spotted until it’s already too late.

Gold mines, of course, can be incredibly profitable. But the other side of the doubloon is that every hour the mine isn’t running, they are losing hundreds of thousands of dollars. That’s why an increasing number of gold mines are looking to load indicating fasteners to provide an operational advantage by limiting downtime, increasing efficiency, and saving money.

Valley Forge & Bolt offers a number of solutions to keep gold mines (and other mines) operating at peak efficiency.

The grinding mills that smash rock and other material into smaller, more manageable bits are expected to run non-stop and trouble-free for three months at a time. Premature bolt failure, like the kind that begins with beachmarks, brings the mills to a halt. One mining engineer estimates that every six hours spent replacing failed fasteners costs his mine $500,000.

Valley Forge offers a family of products that can streamline the grinding mill reline process by telling maintenance staff exactly when they should begin retorquing after a new fastener installation. It is here that Valley Forge’s SPC4® Load Indicating Fasteners and SPC4® 702 Series Wireless Load Indicating System and Load Data Logging System can offer big savings.

When a small number of SPC4® bolts are strategically placed at high-impact areas within a ball mill at relining, they will monitor actual clamp load from within the joint, which can be read remotely by the 702 meter. By measuring this loss of tension, teams can re-torque at an optimal time instead of relying on guesswork.

Jay Palmer, technical sales engineer for Valley Forge, says mines often have an eye-opening experience when using SPC4® for the first time to gauge retorque time. “As a matter of course, they may wait days or weeks to retorque, believing that is how long it takes for tension loss to occur. Instead, SPC4® often indicates that it usually happens within hours of putting the mill back into service after a reline.”

By retorquing much sooner, these mines achieve optimum tension on the bolts in their grinding mills, help eliminate early beachmarks that can lead to future fastener failure and gain a better position to run their grinding mills for the next three months with no unscheduled stoppages.

Palmer recalls a past grinding mill reline for a customer in which only a dozen of its 580 fasteners needed to be SPC4® to achieve an accurate measurement. The remainder of the fasteners were Valley Forge’s Sealing Mill Ridgeback® liner bolts, which prevent racing caused by leakage of slurry through bolt holes. They eliminate the possibility of point loading at the base of the liner pocket and instead distribute a controlled percentage of load along the entire circumference of the pocket base, preventing self-loosening.

Palmer explains that Valley Forge developed the Sealing Mill Ridgeback® liner bolt to improve the reliability of mill liners and liner bolts specifically in ore grinding mill applications. The fastener, designed with a polymer sealing ring that conforms to the liner bolt pocket, “solved bolting problems that our customers were encountering when liners were installed,” said Palmer. “Each bolt now becomes the perfect mate for the liner pocket.”

The Sealing Mill Ridgeback® technology is patented and has been available since late in 2015.

Palmer cautions that all situations are different, and only usage of SPC4® in each specific condition can indicate exact retorquing periods. “However, once they are installed, a wealth of operational information is now there for the operator,” he says. “And what is learned informs future mill maintenance schedules, creates operational efficiencies, or reduces mill maintenance costs.”

Web-based clamp load sensor is IoT-compatible

Phoenix—Dec. 4, 2020—Maintenance engineers in critical environments charged with condition monitoring have long wished the bolts themselves could start the conversation. Now they can. Valley Forge & Bolt has taken their SPC4 ® Load Indicating Technology to a new level with the latest addition to the company’s RTM™ (Remote Tension Monitoring) series of meters—the UHF Band RTM Meter, a wireless bolt monitoring system. The UHF Band RTM Meter operates in 433/868/915 MHz frequencies, which includes the industrial, scientific and medical (ISM) frequency.

This wireless sensor detects and collects the tension level in a bolted joint as read by the company’s SPC4® fastener, and then relays the data to a facility’s condition monitoring/SCADA system. Users can also program the sensor to take measurements at prescribed intervals and send alerts if a bolted joint falls out of chosen tension parameters.

There are several scenarios in which the UHF Band RTM™ Meter’s capabilities will pay dividends for users, but the first is the meter facilitates close monitoring of new fasteners during and immediately after install. The early hours after an initial tightening sequence can be critical to long-term performance because an unexpected loss of tension can affect bolt life.

“The facility manager can set the reading intervals for rapid readings, down to once every second, or for every 10 minutes. He or she can see immediately if a fastener is losing tension and correct it,” said James Brooks, Valley Forge & Bolt’s head of engineering and business development. “Conversely, after enough time has passed and they are satisfied that the tension is holding, the manager can quickly and remotely adjust the reading intervals to be farther apart.”

In the long term, all bolts can be set to broadcast alerts when a chosen tension threshold is crossed.

“Select a tension percentage that is close to your application’s danger or alert zone,” said Brooks. “If needed, a window with upper and lower tension percentage limits can be created. An alert can be sent as an email or as an audible alarm. The user has total flexibility.”

For the first time, the bolt is starting the conversation about whether it needs maintenance or inspection. Managers can also program alert windows during “interest” periods, such as times of suspected greater vibration in a process, to gauge how fasteners are reacting.

With a web-based user interface, users can change parameters for each wireless sensor remotely. “These features have never before been available in a bolting wireless product,” said Brooks. “The UHF Band RTM™ Meter is a game changer.”

In addition, the UHF band attribute will improve battery life and enable increased distance from the probe to the collection device. SPC4® fasteners make it possible to measure the actual tension from within a fastener, providing real-time knowledge of critical joint tension and performance from installation through fastener life. A variety of sensors and meters are available to read, display, and relay this tension information.

Innovative new liner bolts can be seated more securely, prolonging equipment life

Within every ore grinding mill is a slurry that is essential to its processes. However, unconstrained, this mix of water and grit becomes the enemy of the very mill designed to hold it.

Within every ore grinding mill is a slurry that is essential to its processes. However, unconstrained, this mix of water and grit becomes the enemy of the very mill designed to hold it.

When bolts are not properly tensioned, mill liners become loose, and the slurry works its way into the bolt pocket. Eventually, the abrasive slurry leaching into the bolt pocket can result in bolt erosion, causing premature failure of both the bolts and the mill shell.

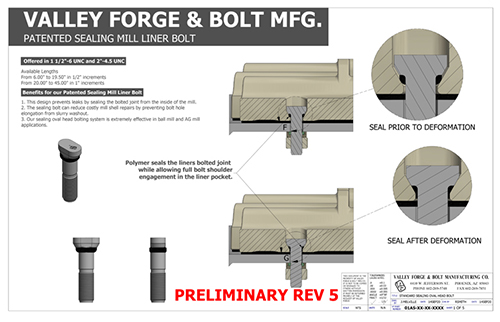

The problem with typical liner bolts is their geometry.

In conventional liners, the oval radius of the bolt is 1/8-inch per side smaller than the oval radius of the liner. The resulting angularity deviation between the liner bolt pocket and bolt creates two high-stress points of contact. This poor interface becomes an issue the moment the mill goes into service, eventually causing premature failure that can require a total shutdown in order to tighten loose bolts or replace broken liners.

Valley Forge & Bolt has developed a liner bolt innovation to improve the reliability of mill liners and liner bolts in ore grinding mill applications. The Sealing Mill Liner Bolt is designed with a polymer sealing ring that conforms to the liner bolt pocket, eliminating gaps and stress points.

“The head shape with the seal conforms to the liner pocket for better fit, so the bolts only need to be re-torqued once,” said Brooks. “The seals also help absorb heavy impacts and reduce the bolts’ chances to loosen.”

The Sealing Mill Liner Bolts produce effective sealing of the bolt to liner pocket throughout the full range of bolt capacity, including during very low loading conditions. Sealing Mill Liner Bolts, as well as the company’s companion product, Sealing Mill Ridgeback® Liner Bolts, hold liners more securely than conventional liner bolts.

“Both the Sealing Mill Liner Bolts’ and Sealing Mill Ridgeback® Bolts’ heads increase contact surface by conforming to the shape of the tapered surface of the pocket. This eliminates points of stress and, with that, problems common to ore grinding mills,” said Brooks. “It gives mines an economical way to maximize the life of their bolts and help prevent expensive unplanned shutdowns.”

For more information, email sales@vfbolts.com or call: 1 (602) 269-5748.

New SPC4™ meter from Valley Forge is designed with mining in mind

To outside eyes, mining’s twin objectives of worker safety and maximum productivity can seemingly be at odds, but that’s never really the case. The truth is, ongoing technological developments consistently improve both. The latest product from Valley Forge & Bolt, a domestic manufacturer of patented bolting products for critical applications, offers a prime example of a manufacturer committing to helping mines perform more efficiently while improving safety.

The new product is the latest meter for its SPC4™ Load Verifying System. The SPC4™ 406A Electronic Meter (VF# SPC4-ASM-406A) is specially designed for accurate performance in heat, humidity, and other demanding environments found in mining. By taking into account mining’s unique environmental factors, the meter works as part of the company’s SPC4™ system to provide to provide accurate clamp load data for critical bolted joints, which leads to a full spectrum of aggregate benefits for total mine operations.

The SPC4™ system encompasses fasteners equipped with Valley Forge load-indicating technology, along with a wide variety of meters to fit a range of applications and environmental conditions. The meters, including analog, digital or Wi-Fi versions, measure tension directly from within the fastener to +/- 5% accuracy. The 406A meter joins this complete offering.

In total, the SPC4™ system directly measures fastener tension to provide the most accurate data possible about the actual load within critical bolted joints. In the field, this information is used to make both installation and maintenance faster and more accurate, create more effective maintenance schedules, and give crucial, early insight into fastener and equipment behavior that might lead to premature failure, allowing it to be corrected before problems arise. The net gain is increased productivity, performance, and safety combined with savings of time and money.

The 406A meter’s prototype was field tested on flange joints in Houston, Texas, and is already in use in mines in South America. It boasts a rugged design with a shock-resistant casing that is IP54-rated for protection against dust and particles. Its internals are specifically engineered to deliver high performance that is unaffected by extreme heat and humidity.

“With the 406A, our aim was to create a meter with the extra durability mining environments need while still maintaining the high degree of accuracy people expect from Valley Forge,” said James Brooks, Valley Forge & Bolt’s director of engineering and new business development.

In addition to these crucial performance factors, the 406A has other features designed with the mine in mind. The ergonomic handheld design was built for ease-of-use in the field. The one-touch operation with a large, visible button is easy to engage without removing PPE gloves, and its large digital display allows for easy reading.

Bluetooth compatibility provides scalability for remote data monitoring and data logging capability. This opens up even more maintenance planning options, as it creates an ongoing record of fastener load changes across a mine’s critical joints. The gathered information provides insight into changes in clamp load, and these data points allow for smarter and more predictable equipment maintenance over time.

“SPC4™ technology has been embraced by customers throughout the mining industry for its accuracy and reliability,” said Brooks. “The 406A meter now becomes the leading choice for mining operations that use handheld meters with their SPC4™ fasteners.”