VFB Interview With Brad Webb of AC Sailing SF

“It all started when Bengt Blenduf, the well-known, international bolting Guru and educator was approached for his design recommendations by the Oracle/BMW racing team for their keel bolts. He thought it would be a great application for our load indicating technology, so he called me and directed me to their engineering. Valley Forge designed the hardware for the Maxbolt™ with the Oracle engineers, as you see it today.”

– Ron Clarke

VFB: How long you have been racing boats Brad?

BW: I started sailing when I was 12, in just a little dingy, in Wellington, NZ. I used to enjoy sailing on my own but for whatever reason, I enjoyed sailing with other people more and as I got further into it, I realized as much as I was quite a good driver, a Helmsman, I was a better crewmember, especially on the bow at the front of the boat. And then, my career happened more by accident then by good management. I decided to take a couple years off just to figure out what I wanted to do with my life: that was 20 years ago. I grew up looking at the big glossy magazines, with nice boats and sun drenched ports, and that seemed to me like a pretty good way to spend a couple of years. I wanted to go and sail the big blue water events, I wanted to sail on big fast boats, so I did. I had this drive to be better, I wanted to do things better every day I went out. I started sailing on the match racing circuits around the world, with some different skippers and my first America’s Cup was in 1995 in San Diego. Again it was more by accident than good management. Between 1995 and 2000, which was the next American’s Cup in New Zealand, I went sailing around the world, and sailed in a lot of different places. I think there was 140 events in 16 different countries over four and a half years. I did a lot of sailing, and sailed with a lot of people, in a lot of different situations and gained a lot of experience. When my second America’s Cup came around in 2000 with America True, the San Francisco team, I was pretty well prepared. Later that year I was picked up by Oracle Racing for the 2003 America’s cup, and I’ve been with Oracle Racing ever since, 5 campaigns and over 14 years.

VFB: Tell us about USA 76, the boat that has Valley Forge Maxbolts™ in the keel?

VFB: Tell us about USA 76, the boat that has Valley Forge Maxbolts™ in the keel?

BW: I sailed in the International America’s Cup Class (IACC) for four America’s Cups, from 1992 to 2007. That is what USA 76 is. The IACC, and the USA 76, was a great, great class, for 15 years, they built 100 boats. They are all sequential, so USA 76 is the 76th boat built. We were never successful winning the Cup in that class, but they were just a great boat to sail. We sailed with 17 people on those. Everyone had very, very specific roles, and the choreography that needed to happen on board to get the boat around the course, changing sails and sail it well, was quite detailed. If you got it right, you could have a great day out. And if you got it wrong, it was a bad day. The boats were very fast. We would sail around in those boats at 10 to 15 knots. Then we transitioned into the big T Hulls, and now we have transitioned into foiling catamarans, which are now sailing around at 45 knots. Quite a big jump in just a few years! But I bought USA 76 because I thought San Francisco needed some kind of connection to the America’s Cup. It’s a great boat, I know it well, and we put it together here in 2011, and we have been running it as a charter business out of Pier 39, coming up on 4 years now.

VFB: What distances did USA 76 race?

BW: We used to sail the IACC on a course that was effectively 12 miles, although you cover a lot more distance when you’re zigzagging up. Those races were about an hour to an hour and half long. We are now doing the same distance for the last America’s Cup in 2013, in San Francisco, doing the same distance in about 25 minutes in the catamarans. Still kind of doing the same distance but screaming around the race course.

VFB: What about the conditions of the race? What variation is there that the boats sail in?

BW: It really depends on the venue. The America’s Cup was held for a long, long time in Newport, Rhode Island, which was fairly benign. It would be 10-15 knots and fairly flat water, but quite consistent. When Australia won in 1983, they broke the longest winning streak in history and took the event down to Perth. The Regatta was held offshore there, and it was extremely windy with big waves. For those who watched, like me as a kid, it was extremely exciting because it was wet ‘n wild with thrills and spills. Then it was won again by the American’s and taken to San Diego which is inherently light, so the yachting there wasn’t all that exciting. New Zealand won it in 1995 and took it to New Zealand. That really showed what sort of range these boats can go through. We would have very light winds or very heavy, in fact in 2000 it was extremely windy. But again, you can have days that were light and then days that were wet ‘n wild and great TV viewing. They generally stop racing the boats at about 30 knots of true wind. For a couple of reasons, safety primarily, but after that, it’s tough to even watch and it’s even tougher for the race committee to set a fair course. At that point, it gets pretty extreme, boats are dragging anchors and it gets a little brutal. But that has generally been the range, from about 7 to 27 knots, so there is a significant amount of variation in the sailing conditions.

VFB: How much are the boats sailing? In terms of the years that the Maxbolts™ have been in the keel?

VFB: How much are the boats sailing? In terms of the years that the Maxbolts™ have been in the keel?

BW: For the IACC [USA 76 class] we used to do a lot of sailing, we would set up at a venue, or different venues around the world and do a lot of sailing. Once you had them together, they were an easy boat to put in the water and go sailing. The catamarans are logistically a little bit harder, because you have to put the wing and platform in everyday, and you have to use a crane. Just logistically they are a lot tougher. The cut boats we used to sail a lot, especially when we were based in Valencia. We sailed probably every other day for three years. That was a lot of sailing. Then, when we weren’t sailing, we were off sailing some other boats. So the USA 76 has been all over the world sailing far and wide; Auckland, Australia, all around Europe, lots of sailing in Europe, and both coasts of the USA.

VFB: How was USA 76 designed?

BW: It’s generally started using CSD analysis and making a hull shape, that is as fast as it can be built. And then the next part is engineering a structure that is as light, but as strong as it can be built. That then becomes part of the keel equation. But then you have to build everything else around it; the sails and the systems on board. Again, the lighter that you can make everything in the hull, and everything above the wood line, the more lead you could put in the bulb, because it was an overall weight that was part of the rule. Which basically makes the boat more powerful, which made the boat faster. If you could make the boat more powerful, it basically meant you were putting more lead in the bulb, but it then also meant that your keel, keel structure and all your fastenings needed to be engineered to take all that extra load. It’s a very complicated puzzle that needs to be just about perfect to work. There’s no room for error.

VFB: Where there bolting issues being encountered when you first came to Valley Forge for fasteners?

BW: There wasn’t necessarily a bolting issue, the Maxbolts where just the right product and application because you can see what the loading was. You can see that you were getting the numbers that the designers were asking for. We rely HEAVILY on analytics and engineering and design numbers, not only to build it, but to maintain it and monitor the boat, day in and day out. [When racing] we would take the keel on and off of this boat, probably once a month just to check it and make sure nothing was going wrong. For me it’s just all about reliability. Reliability was a HUGE thing for us when we were racing this boat because we had to finish races. We have to have faith in our gear. My mentality now is on a commercial operation, inspected by the coast guard, and I have paying passengers onboard. My liability is huge. Keels have fallen off and broken off America’s Cup boats in the past. Generally not because of the bolts, but for other reasons through fatigue and poor engineering. That still doesn’t mean that I want to risk sitting back and not doing anything. I have a lot of faith in how this keel was engineered. On these boats, the keel is just a huge, huge deal. If you engineered the hull and the rig and everything else light, there was more lead you could put downstairs. But it also meant the keel bolts were going to be working a lot harder, so the keel bolts were a huge part of the equation when these boats were being built, the way they’re engineered and the way the whole structure was engineered around the keel. Everything else doesn’t see that kind of load. I am quite close to the guy that designed the keel in the first place. We constantly talk about cycles and fatigue that the boat is going through. We took a lot of lead out of the bulb when we put it back in the water [commercially] and took some sailing rear off. So the bolts aren’t under what they were designed for, they aren’t seeing the design load they originally engineered for. It would be quite a lot lower. However, they are seeing a lot more cycles than they were originally engineered for. Which is why we haven’t had a lot of concern, because we think there have been some tradeoffs. Now that it’s been four years, we think the prudent thing is to take them out, check them, have them tested, put new ones in and see where we stand and ensure that we have confidence in the boat forward.

VF: Tell us more about the Maxbolts™ in USA 76?

VF: Tell us more about the Maxbolts™ in USA 76?

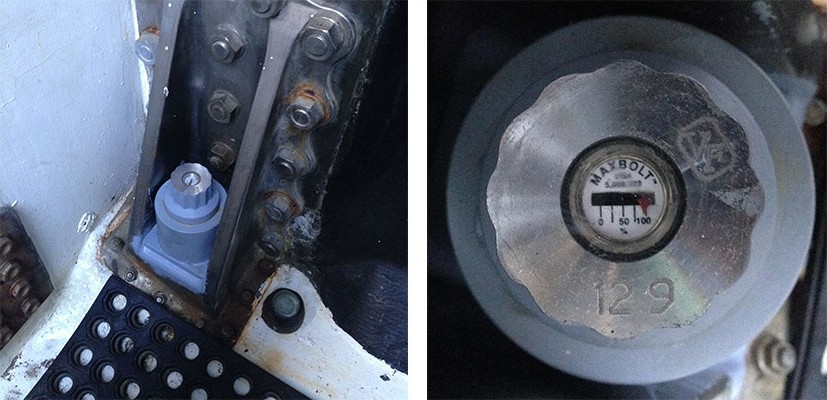

BW: The first set, they used to go in and out every month. That was when we were racing. Since I have bought the boat, and have a commercial license, we put a new set of bolts in the boat in 2011 and haven’t touched them since. We originally put them up to about 80% of their max loading, which we were happy with, and they haven’t moved. We have made sure that we have kept them nice and greased because they are in a pretty harsh environment, so we try to look after them as best we can. Now we are taking them out and putting a brand new set in. We are going to send them back to Valley Forge for testing and that will give us an accurate picture of life and the environment that these bolts have been in. What we are going to learn when the new bolts come and we swap them out, is if there has been any fatigue on them, or excessive amounts of corrosion, just what’s going on. For a number of things, but mainly we can learn what kind of long term environment they can go into. For us, it gives us an idea of where we are in the cycle of these bolts. When we put these brand new ones in and send the other back and we find that they are absolutely pristine, then we know the least amount of time we can get out of them, without any concerns.

Post interview update: The USA 76 was taken out of the water on March 18th at the KKMI Marine Facility in Port Richmond, a first class boat yard in San Francisco and AC Sailing’s first choice for haul out and maintenance needs. They removed the in service Maxbolts™, and installed the brand new set. The photos show her out of the water with her 14 foot long keel and 40,000 pounds of lead attached at the bottom. You can see the installation using the VF hydraulic wrench and the new bolts in position and tensioned. The bolts were fully lubricated, then painted with an epoxy protective coating after install.